Lifting screw jacks are essential mechanical devices used for lifting, lowering, or positioning heavy loads with precision. These devices are widely used in industries such as automotive, construction, machinery, and even in smaller-scale applications like home repairs. Screw jacks work by converting rotational motion into linear motion through the use of a screw thread, providing an efficient way to lift heavy objects with minimal effort.

While all lifting screw jacks perform the same basic function, there are different types of designs that cater to various requirements in terms of load capacity, application, and ease of use. In this article, we will explore the three primary types of lifting screw jack designs: the manual screw jack, the mechanical screw jack, and the electric screw jack.

1. Manual Screw Jack

Overview:

The manual screw jack is the simplest and most traditional design. It is operated by turning a hand crank or lever, which rotates a screw that raises or lowers the load. This type of jack is often used in scenarios where a modest load needs to be lifted, such as in car maintenance, light construction work, or lifting machinery in smaller workshops.

How It Works:

In a manual screw jack, the operator turns the handle or crank, causing the lead screw to rotate. This rotation moves the lifting nut along the threaded shaft, which in turn raises or lowers the load. Since the design relies on manual effort, it’s generally slower and more labor-intensive than powered alternatives.

Advantages:

-

Cost-effective: Manual screw jacks are affordable and easy to maintain.

-

Portability: Being simple and compact, they are easy to transport and store.

-

Reliability: Fewer moving parts mean there is less that can go wrong, making it a highly reliable tool.

Limitations:

-

Manual effort required: Lifting larger loads can be physically demanding and time-consuming.

-

Slow operation: The manual process can be slower compared to other types, especially for heavy loads.

Common Applications:

-

Car jacks

-

Boat lifts

-

Small-scale construction or industrial lifting tasks

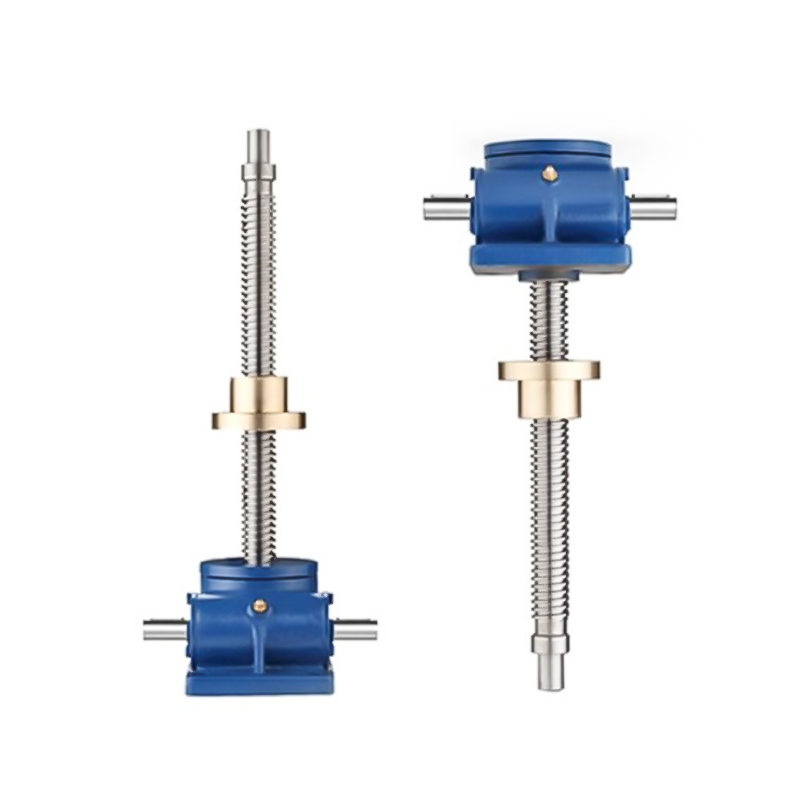

2. Mechanical Screw Jack

Overview:

Mechanical screw jacks are similar to manual screw jacks but incorporate additional mechanical components to enhance their lifting capability. These jacks often include a gear mechanism or other types of mechanical assistance to reduce the amount of manual effort required for lifting heavy loads. The gear mechanism typically includes a reduction system that multiplies the input force, making lifting heavy loads easier.

How It Works:

In a mechanical screw jack, the operator turns the handle, which rotates a set of gears connected to the screw. The gears reduce the effort needed to turn the screw, thereby multiplying the force applied by the user. As a result, the operator can lift much heavier loads with less effort compared to a standard manual screw jack.

Advantages:

-

Lifting heavy loads with less effort: The mechanical assistance allows the jack to lift heavier loads with less manual effort.

-

More control: The gear mechanism often provides more precise control over the load’s movement.

-

Durability: Mechanical screw jacks are designed for long-term use and can withstand higher loads.

Limitations:

-

More complex: With additional gears and parts, mechanical screw jacks are more complex and can require more maintenance.

-

Higher cost: Due to the added components and materials, they are more expensive than manual screw jacks.

Common Applications:

-

Heavy machinery lifting

-

Industrial lifting in construction sites

-

Aircraft maintenance

3. Electric Screw Jack

Overview:

Electric screw jacks are powered by electricity and are designed for high-efficiency lifting of very heavy loads. They are often used in situations where frequent or large-scale lifting is required, and manual effort is impractical. Electric screw jacks are typically integrated with a motor that drives the screw mechanism, allowing for fast and easy lifting without human effort.

How It Works:

Electric screw jacks use an electric motor to rotate the screw, which in turn raises or lowers the load. The motor is typically controlled via a switch or remote control, which makes the operation quick and efficient. Some models may include a gearbox to enhance the lifting capacity and control speed.

Advantages:

-

Effortless operation: Since the lifting is powered by electricity, there is no physical effort required by the operator, making it ideal for heavy or frequent lifting tasks.

-

Fast and efficient: Electric screw jacks are faster than manual and mechanical alternatives, making them suitable for environments where time is critical.

-

Precision control: They often come with digital or remote controls, providing greater precision and ease of operation.

Limitations:

-

Dependency on power: Electric screw jacks require a power source, which could be a limitation in remote or off-grid locations.

-

Higher cost: Due to the motor and electronic components, electric screw jacks tend to be more expensive than manual or mechanical types.

-

Maintenance: Electrical components may require more maintenance and repairs over time, especially with heavy use.

Common Applications:

-

Large-scale industrial lifting

-

Vehicle and equipment lifts in garages and workshops

-

Agricultural machinery handling

-

Aircraft or heavy equipment maintenance

Conclusion

Each of the three types of lifting screw jacks—manual, mechanical, and electric—has its own set of advantages and limitations, making them suitable for different applications. When choosing a lifting screw jack, it’s important to consider factors such as the weight of the load, the frequency of use, the available power sources, and budget constraints.

-

Manual screw jacks are ideal for light-duty tasks where cost-effectiveness and portability are key.

-

Mechanical screw jacks are better suited for medium-duty applications that require more lifting power with less effort.

-

Electric screw jacks are the go-to choice for heavy-duty, high-frequency lifting where speed, efficiency, and minimal effort are paramount.

By understanding these three designs and their respective features, you can select the right lifting screw jack that fits your needs and ensures safe, efficient operation for your tasks.

English

English 中文简体

中文简体 Español

Español русский

русский عربى

عربى