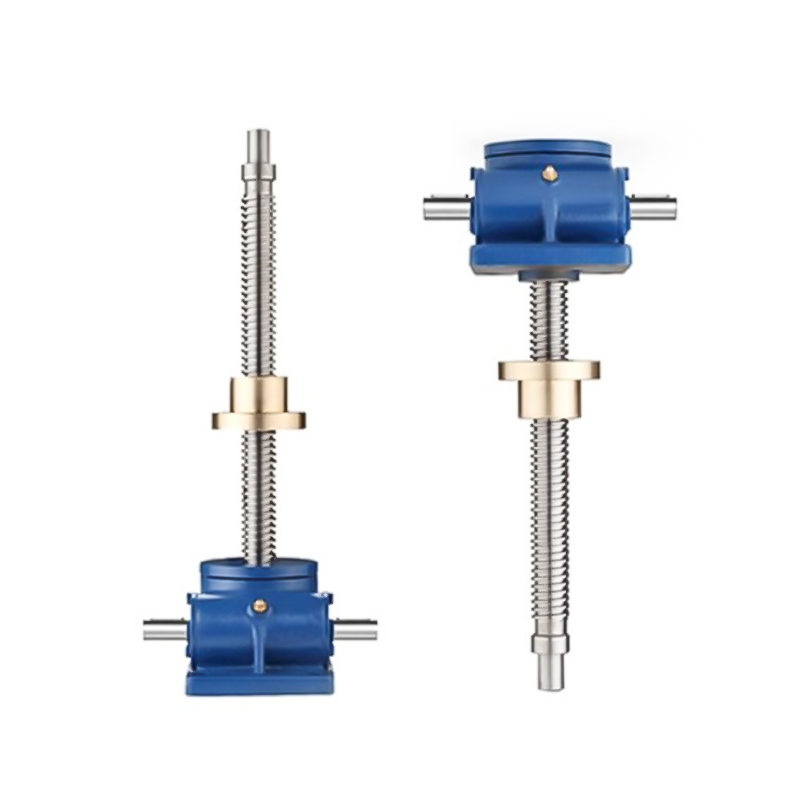

Soverchannel Industrial CO.,Ltd. is China Jack Screw Suppliers and Jack Screw company, a production, research, and development, sales one of the non-standard and standard parts of the bolt production enterprise, for many years, it has committed to the production of automotive fasteners, with advanced technology and strict inspection specifications, to provide customers with high-quality products, while professional custom non-standard bolts, shaped parts, over the years of industry experience has accumulated a good reputation. The company's main products include bolt products, nuts, steel processing, welding, and other non-standard-shaped parts.

-

Full Threaded Rod Bars vs. Partial Threaded Rods: Key Differences Threaded rods are essential fasteners in construction, machinery, and industrial applications. Choosing between full threaded rod bars...

READ MORE -

Introduction to Automotive Fasteners Automotive fasteners are essential components that secure parts of a vehicle together, ensuring safety, reliability, and structural integrity. They include bolts, ...

READ MORE -

Introduction to M8, M10, M12, and M14 Screws and Nuts Metric screws and nuts, such as M8, M10, M12, and M14, are widely used fasteners in mechanical, automotive, construction, and industrial applicati...

READ MORE

Lifting Screws vs. Traditional Jacks: A Comparative Analysis

Lifting screws and traditional jacks are essential tools used in various applications to lift or move heavy loads. Understanding the differences between these two mechanisms is crucial for selecting the right equipment for specific tasks.

Advantages

Lifting Screws:

Precision Control: Lifting screws allow for fine adjustments and precise positioning, making them ideal for applications requiring accuracy.

Durability: Made from high-strength materials like steel or stainless steel, lifting screws are designed to withstand heavy loads and harsh conditions.

Mechanical Advantage:The screw mechanism provides a high mechanical advantage, allowing users to lift significant weights with less input force.

Traditional Jacks:

Quick Operation: Traditional jacks, especially hydraulic jacks, can lift loads quickly and with minimal effort, making them efficient for urgent tasks.

Versatility: Traditional jacks are available in various designs, catering to a wide range of applications and load capacities.

Ease of Use: Many traditional jacks are straightforward to operate, requiring less technical knowledge than lifting screws.

Limitations

Lifting Screws:

Speed of Operation:Lifting screws typically operate slower than traditional jacks, which may not be ideal for time-sensitive tasks.

Space Requirements:The vertical movement of lifting screws may require more space compared to some traditional jacks, which can operate in tighter environments.

Complexity:Installation and adjustment of lifting screws may require more technical knowledge compared to the straightforward operation of traditional jacks.

Traditional Jacks:

Precision Limitations:While traditional jacks are efficient for lifting, they may not offer the same level of precision and control as lifting screws.

Load Capacity Limitations:Some traditional jacks may have lower load capacities compared to heavy-duty lifting screws, making them unsuitable for certain applications.

Potential for Failure:Hydraulic jacks can be prone to leaks or failure under extreme conditions, potentially leading to safety hazards.

Materials Matter: Why High-Strength Steel is Essential for Lifting Screws

When it comes to the design and manufacturing of lifting screws, the choice of material plays a crucial role in determining their performance, durability, and overall effectiveness. High-strength steel has become the material of choice for many applications involving lifting screws.

Exceptional Strength-to-Weight Ratio

High-strength steel offers an outstanding strength-to-weight ratio, making it an ideal choice for lifting screws. This means that while the material is strong enough to handle significant loads, it does not add excessive weight to the overall assembly. The ability to lift heavy loads without increasing the weight of the lifting mechanism is vital in applications where space and weight considerations are paramount, such as in aerospace and automotive industries.

Resistance to Deformation

Lifting screws are subjected to substantial forces during operation, and the materials used must resist deformation under load. High-strength steel is engineered to withstand high tensile and compressive stresses without yielding or permanently deforming. This characteristic ensures that lifting screws maintain their precise dimensions and functionality over time, which is crucial for applications requiring accurate positioning.

Durability and Wear Resistance

In many applications, lifting screws operate in harsh environments that can lead to wear and tear. High-strength steel exhibits excellent durability and wear resistance, allowing lifting screws to maintain their performance even under challenging conditions. The material can withstand abrasion and friction, which is particularly important in applications like construction and industrial machinery where screws are frequently engaged and disengaged.

Corrosion Resistance

While high-strength steel provides exceptional strength, it can also be treated or alloyed to enhance its corrosion resistance. This is especially important for lifting screws used in outdoor or humid environments, where exposure to moisture and other corrosive elements can compromise performance. By using high-strength steel with appropriate protective coatings, manufacturers can ensure that lifting screws remain functional and reliable over extended periods, reducing maintenance costs and downtime.

Cost-Effectiveness

High-strength steel is often more cost-effective compared to other materials with similar strength properties, such as titanium or specialized alloys. This cost-effectiveness makes high-strength steel a practical choice for manufacturers looking to produce lifting screws without compromising on quality or performance. The availability and affordability of high-strength steel also contribute to its widespread use in various industries.

Versatility in Design

High-strength steel can be easily machined and formed into various shapes and sizes, allowing for versatility in the design of lifting screws. This adaptability enables engineers to create custom solutions tailored to specific applications, whether for industrial machinery, automotive systems, or other lifting mechanisms. The ability to work with high-strength steel facilitates the development of innovative designs that enhance the functionality of lifting screws.

Compliance with Industry Standards

Lifting screws made from high-strength steel can meet or exceed industry standards and specifications for performance and safety. Compliance with these standards is critical in applications where reliability and safety are paramount, such as in construction and heavy machinery. Using high-strength steel ensures that lifting screws are manufactured to meet rigorous quality control measures, providing peace of mind for users.

English

English 中文简体

中文简体 Español

Español русский

русский عربى

عربى