Soverchannel Industrial CO.,Ltd. is China Full Threaded Rod Bar Suppliers and Full Threaded Rod Bar company, a production, research, and development, sales one of the non-standard and standard parts of the bolt production enterprise, for many years, it has committed to the production of automotive fasteners, with advanced technology and strict inspection specifications, to provide customers with high-quality products, while professional custom non-standard bolts, shaped parts, over the years of industry experience has accumulated a good reputation. The company's main products include bolt products, nuts, steel processing, welding, and other non-standard-shaped parts.

-

Full Threaded Rod Bars vs. Partial Threaded Rods: Key Differences Threaded rods are essential fasteners in construction, machinery, and industrial applications. Choosing between full threaded rod bars...

READ MORE -

Introduction to Automotive Fasteners Automotive fasteners are essential components that secure parts of a vehicle together, ensuring safety, reliability, and structural integrity. They include bolts, ...

READ MORE -

Introduction to M8, M10, M12, and M14 Screws and Nuts Metric screws and nuts, such as M8, M10, M12, and M14, are widely used fasteners in mechanical, automotive, construction, and industrial applicati...

READ MORE

Trapezoidal Lead Screws in Jacks: Ensuring Safe and Efficient Heavy Lifting

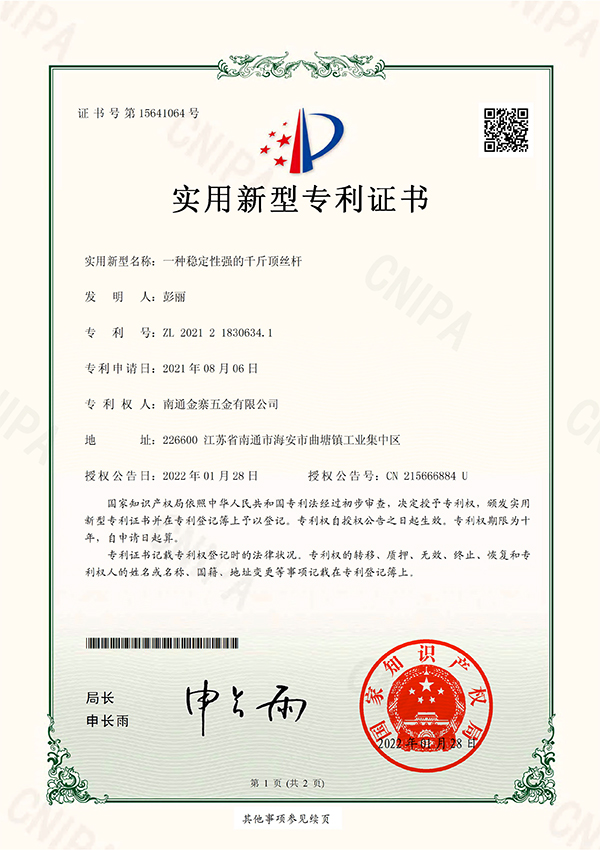

Trapezoidal lead screws are integral to the functionality of jacks, providing the precise and reliable conversion of rotary motion into linear motion, which is essential for lifting heavy objects. The distinctive trapezoidal thread design offers a larger contact surface area compared to traditional V-threads, enhancing the screw's ability to handle substantial loads. This increased contact area distributes forces more evenly, allowing for greater load-bearing capacity and improved mechanical advantage. As a result, trapezoidal lead screws enable jacks to achieve stable and powerful lifting forces, ensuring safe and efficient heavy lifting operations.

The choice of materials for trapezoidal lead screws is also a key factor in their performance. Typically made from durable materials such as stainless steel, bronze, or alloy steel, these screws exhibit high wear resistance, strength, and a long operational lifespan. Stainless steel offers excellent corrosion resistance, making it ideal for applications where exposure to moisture or chemicals may occur, such as in construction sites or outdoor environments. Bronze, on the other hand, provides good self-lubricating properties, which can help reduce friction and extend the life of the screw and nut assembly.

Another essential aspect of trapezoidal lead screws used in jacks is the inclusion of anti-backlash nuts, which are specifically designed to minimize the clearance between the screw and the nut. By reducing backlash, these nuts enhance positioning accuracy and improve overall performance, particularly in applications where precision is critical. The anti-backlash feature not only increases the system's reliability but also helps to maintain smooth operation under varying load conditions, thus reducing wear and tear on the components.

The trapezoidal lead screw's role in jacks extends beyond merely lifting heavy objects; it also plays a part in ensuring the stability and safety of the lifting process. The thread profile's design provides resistance against sudden load shifts, which can occur when heavy objects are being moved or when the jack is used on uneven surfaces. This resistance to load-induced displacement is vital for maintaining control during lifting, especially in situations where safety is a primary concern, such as in automotive repairs or industrial maintenance tasks.

In addition to their use in automotive and industrial jacks, trapezoidal lead screws are also found in a variety of other lifting and positioning applications. For instance, they are commonly used in mechanical actuators, where they facilitate the precise movement of heavy equipment or machinery components. In the construction industry, jacks equipped with trapezoidal lead screws can be used for tasks such as lifting beams, leveling foundations, or supporting structural elements during assembly. The versatility of trapezoidal lead screws makes them an essential component in any setting that requires controlled linear motion and heavy lifting capabilities.

The design of trapezoidal lead screws allows them to achieve a good balance between strength and smooth operation, making them suitable for both medium and heavy-duty applications. Their ability to perform effectively under various loads and conditions ensures that jacks equipped with these screws can handle a wide range of lifting tasks, from light vehicle maintenance to the raising of large industrial machinery. By providing consistent performance and durability, trapezoidal lead screws help to extend the service life of jacks, reducing the need for frequent maintenance or replacement.

Furthermore, the manufacturing process of trapezoidal lead screws involves stringent quality control measures to ensure that each component meets the required specifications for load capacity, material properties, and dimensional accuracy. Nantong Jinzhai Hardware Co., Ltd., a company specializing in both standard and custom fasteners, has developed a reputation for producing high-quality trapezoidal lead screws. Their expertise in advanced manufacturing techniques and strict quality inspection protocols ensures that the screws deliver reliable and consistent performance, even in the most demanding applications.

Maintenance Tips for Prolonging the Life of Your Trapezoidal Lead Screws

Trapezoidal lead screws are essential components in various mechanical applications, particularly in linear motion systems. Proper maintenance is crucial to ensure their longevity, performance, and reliability. Here are some key maintenance tips to help you prolong the life of your trapezoidal lead screws:

Regular Lubrication:One of the most effective ways to maintain trapezoidal lead screws is through regular lubrication. The lubricants reduce friction between the screw and the nut, minimizing wear and heat generation. It is essential to use the right type of lubricant that suits your application, whether it’s grease or oil. Apply lubricant periodically, especially after extended use or when operating in harsh environments.

Inspect for Wear and Damage:Routine inspections are vital to identify signs of wear or damage. Check for any visible wear on the threads, such as flattening or scoring, which can impact performance. Additionally, inspect the nuts for signs of degradation or backlash. If you notice any significant wear, consider replacing the affected components before they fail completely.

Clean the Lead Screw Assembly:Dust, dirt, and debris can accumulate on the lead screw assembly, leading to increased friction and wear. Regularly clean the lead screw and nut assembly using a soft cloth or brush to remove any contaminants. In some cases, using a mild solvent can help dissolve stubborn grime. Ensure the assembly is thoroughly dried before reapplying lubricant.

Ensure Proper Alignment:Misalignment of the lead screw can lead to uneven wear and increased stress on both the screw and nut. Regularly check the alignment of your trapezoidal lead screw within its assembly. Adjustments may be necessary to ensure that the screw operates smoothly along its intended path without undue strain.

Monitor Operating Conditions:Be mindful of the operating conditions of your trapezoidal lead screws. Extreme temperatures, moisture, and corrosive environments can significantly affect their performance and lifespan. If your application exposes the screws to harsh conditions, consider using materials or protective coatings that enhance corrosion resistance or adjust your maintenance schedule accordingly.

Use Anti-Backlash Nuts:Incorporating anti-backlash nuts can help reduce play in the lead screw assembly, improving positioning accuracy and minimizing wear. These specialized nuts are designed to eliminate gaps between the screw and nut, thereby enhancing overall performance and prolonging the life of the lead screw.

Follow Manufacturer Guidelines:Always refer to the manufacturer's recommendations for maintenance practices specific to your trapezoidal lead screws. These guidelines typically provide valuable insights into lubrication intervals, cleaning methods, and load capacities. Adhering to these recommendations will ensure that you are taking the appropriate steps to maintain optimal performance.

Avoid Overloading:Exceeding the recommended load capacity can lead to premature wear and potential failure of your trapezoidal lead screws. Ensure that the application stays within the specified load limits. Implementing safety factors in design can also provide additional protection against unexpected overload conditions.

English

English 中文简体

中文简体 Español

Español русский

русский عربى

عربى